A CNC machine is a computer-controlled tool that automates many machining tasks and provides an extremely high degree of accuracy. Designers create CAD files for the part, which contain the dimensions and specifications of the structure. Once these files have been created, the designers must convert them into the CNC code format using CAM software. A CAM file is a digital version of the CAD file that is translated into the necessary instructions that a CNC machine can use to create the required part.

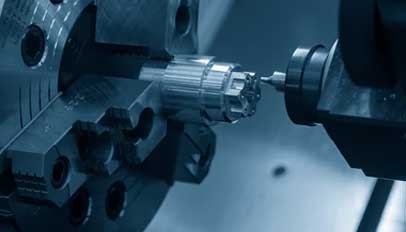

Definition of CNC Machine?

A CNC machine can be operated by a human operator, or it can be controlled by software. It operates by entering a computer program with letters and numbers, which guide the different parts of the machine over a certain distance. Basic mills can operate on a three-axis system, but some newer models can operate on up to six. Lath cutting can be done with indexed tools and high-velocity.

Implement of CNC Machines

CNC machines can implement various tools and components that allow them to produce an almost limitless range of goods. They can make intricate cuts in a matter of minutes, and can even be programmed to perform audits and tool changes. They can also produce highly detailed products. This means that there is no need for human input in the manufacturing process. A CNC machine can produce precision parts in record time. It is also capable of creating parts that require a large amount of machining.

How CNC Machines Work?

A CNC machine can cut, drill, turn, mill, and shape raw materials. The CNC operator must have high-level accuracy to use the CNC. This makes it one of the most accurate tools in the manufacturing industry. A CNC operator also has the advantage of being extremely precise. They are able to make very complex shapes and designs without any human intervention. Whether a CNC operator is operating a CNC machine, he or she must be highly skilled.

CNC Machine Program Code

A CNC machine uses a G-code language to communicate with a computer. A CAM file is a computer program that allows the CNC machine to understand different shapes and angles. This language is called a G-code. These programs are translated by a CNC mill. This type of machine can move the spindle of a milling axis to create complex shapes. The resulting products can be made with these machines.

Types of CNC Machine

A CNC machine is the most versatile type of machine available in the manufacturing industry. Compared to a traditional machine, a CNC can perform many tasks that a manual machine cannot. For example, it can create intricate shapes and designs, allowing for a vast range of products to be manufactured. Another major benefit of a CNC is its ability to expand the capabilities of a manufacturing business. It is also an ideal tool for making prototype parts and reducing costs.

Advantages of CNC Machine

A CNC machine has a lot of advantages over a traditional machine. It can run a program in the background of a factory. The software that is used to program a CNC machine is called CAM (Computer Aided Manufacturing). This software helps the CNC operator create tool paths based on a 3D model of the part. While CAM is helpful for operating a CNC, it isn’t an effective way to run a CNC.

Conclusion

Most CNC machines are programmed to perform a specific function. The first step of programming a CNC machine is to translate the computer-aided drawings into a CAD program. The software then directs the CNC machine to perform the desired function. The second step is to test the new code. During the testing phase, the machine operator will ensure that the new code is working properly. In a typical manufacturing company, the process will take about a minute.